Since 1972, DILIPLAST has specialised in the injection moulding of plastics, with a capacity range from 80 to 180 tons. Over more than fifty years of activity, we have consistently invested in cutting-edge technologies to ensure high-quality mass-produced components. We manufacture caps for aerosol cans and aroma-preserving lids for metal tins.

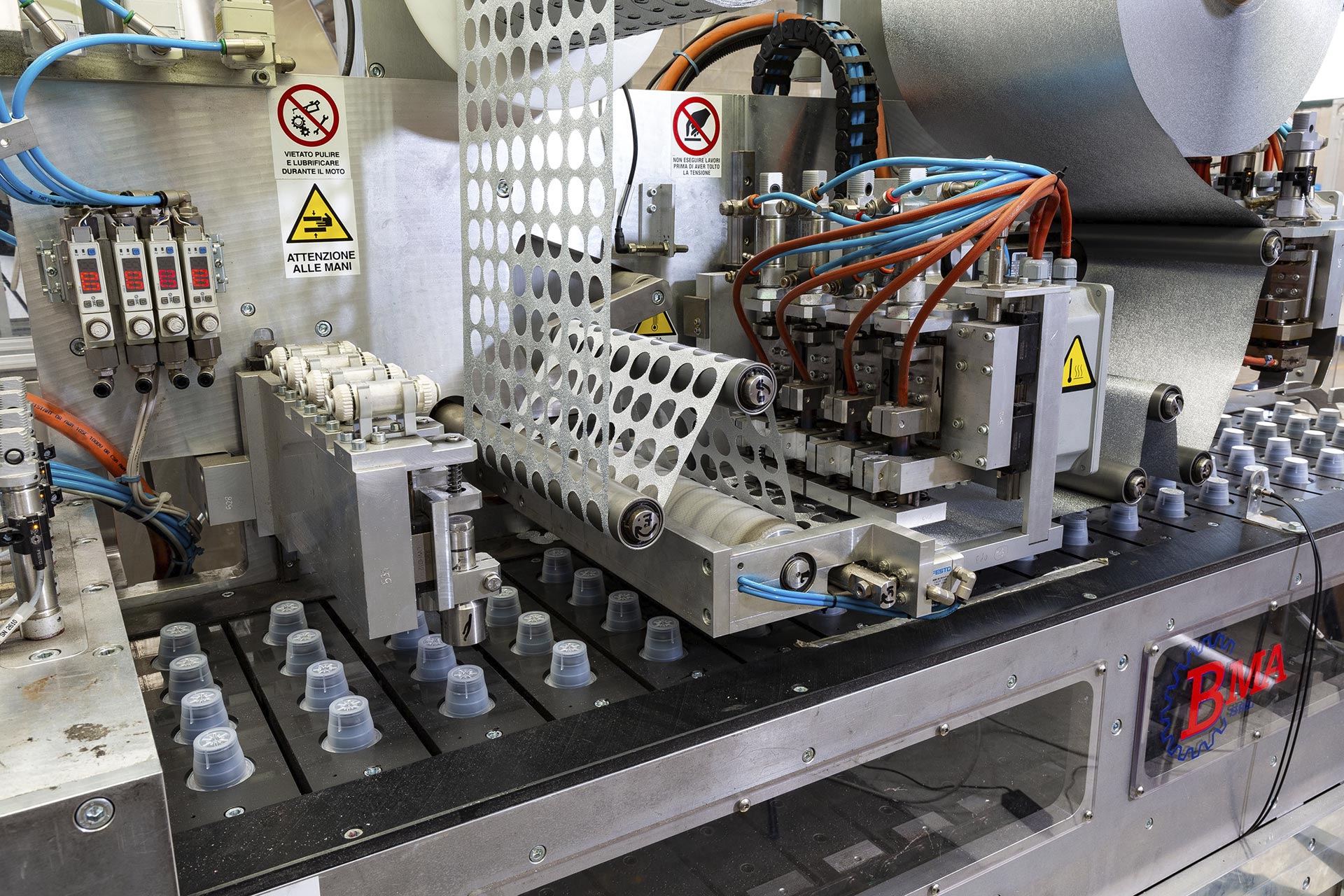

Since 2000, we have specialised in the design and production of coffee and soluble beverage capsules compatible with the main dispensing systems on the market, as well as proprietary closed systems exclusively for our clients.

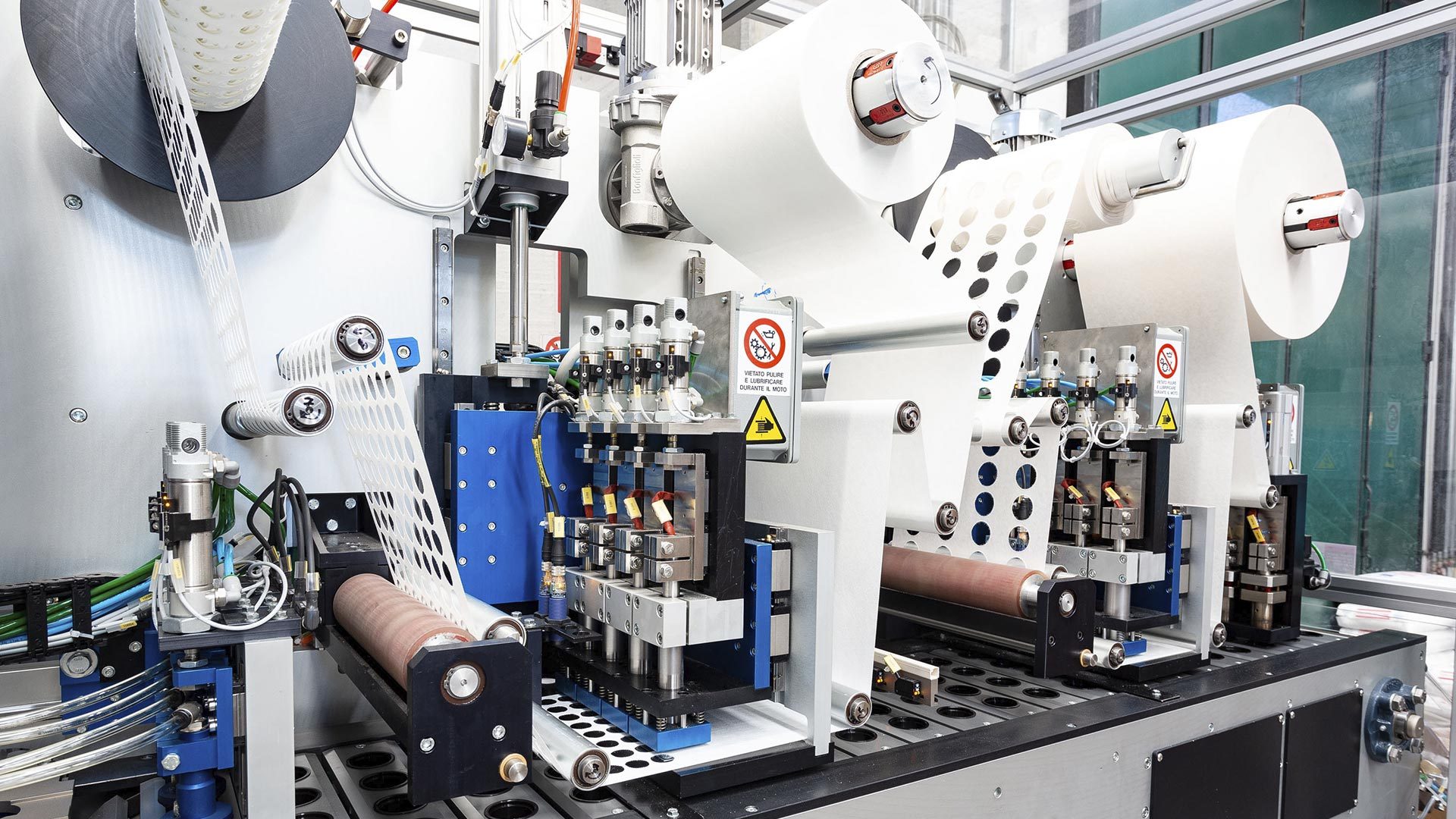

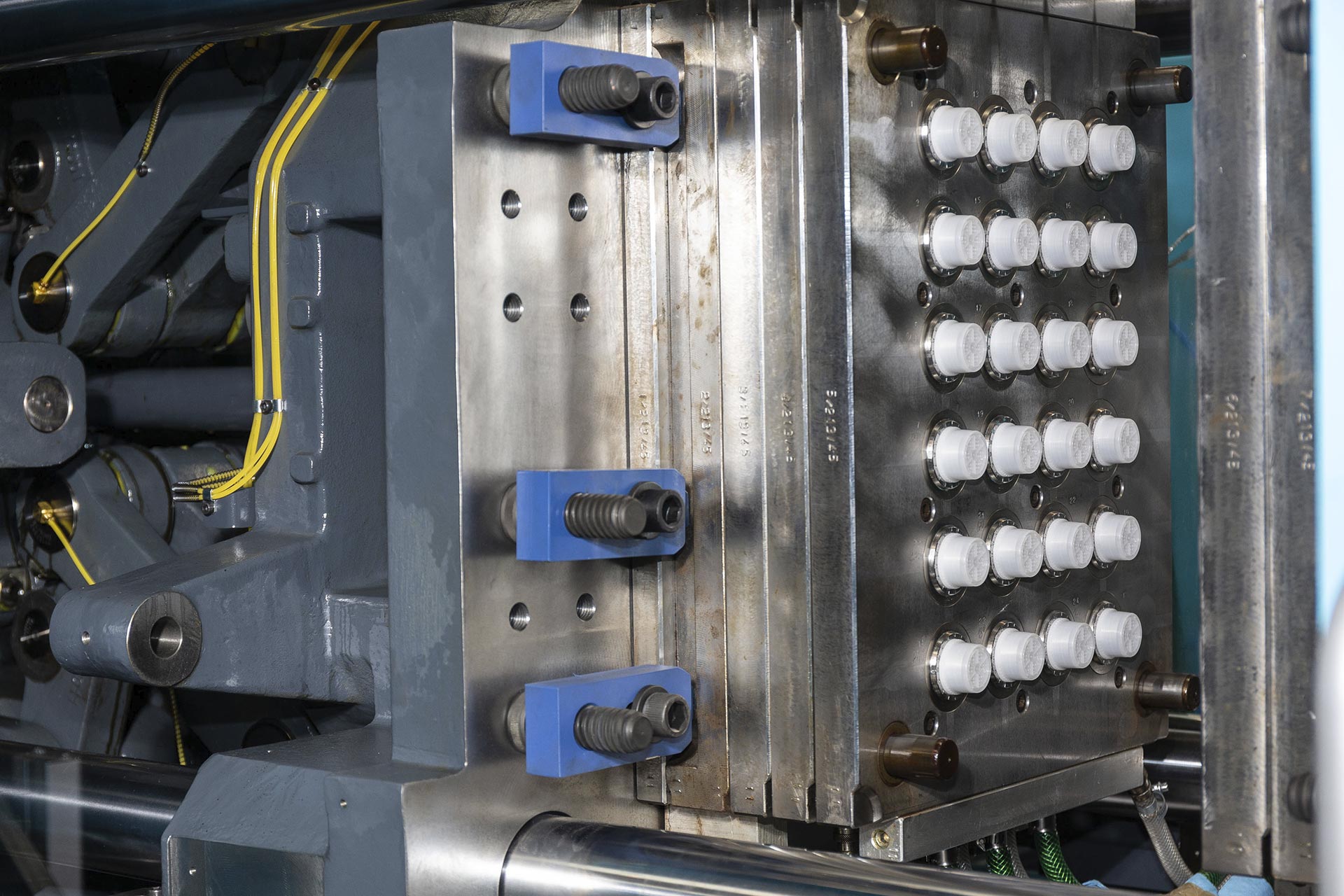

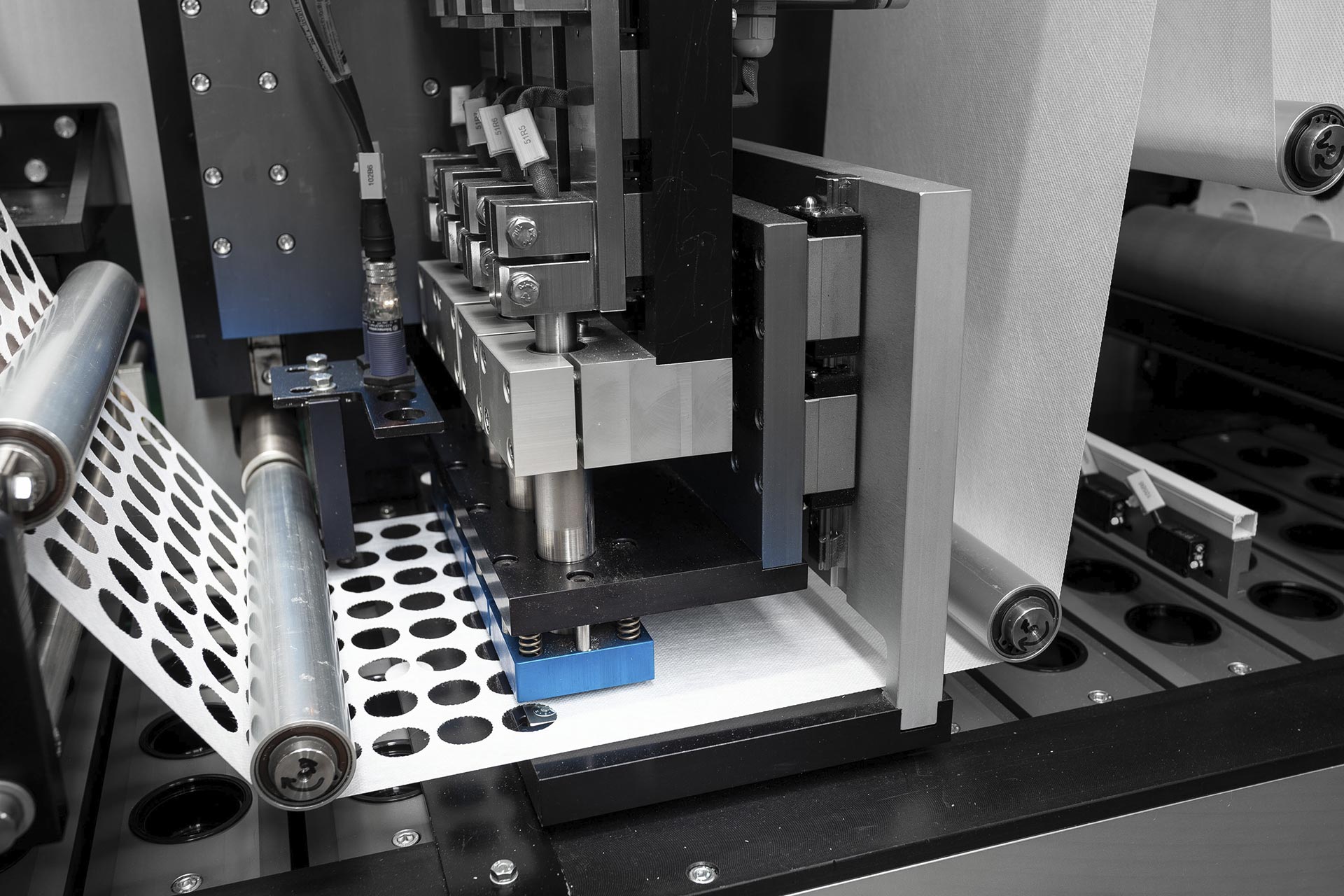

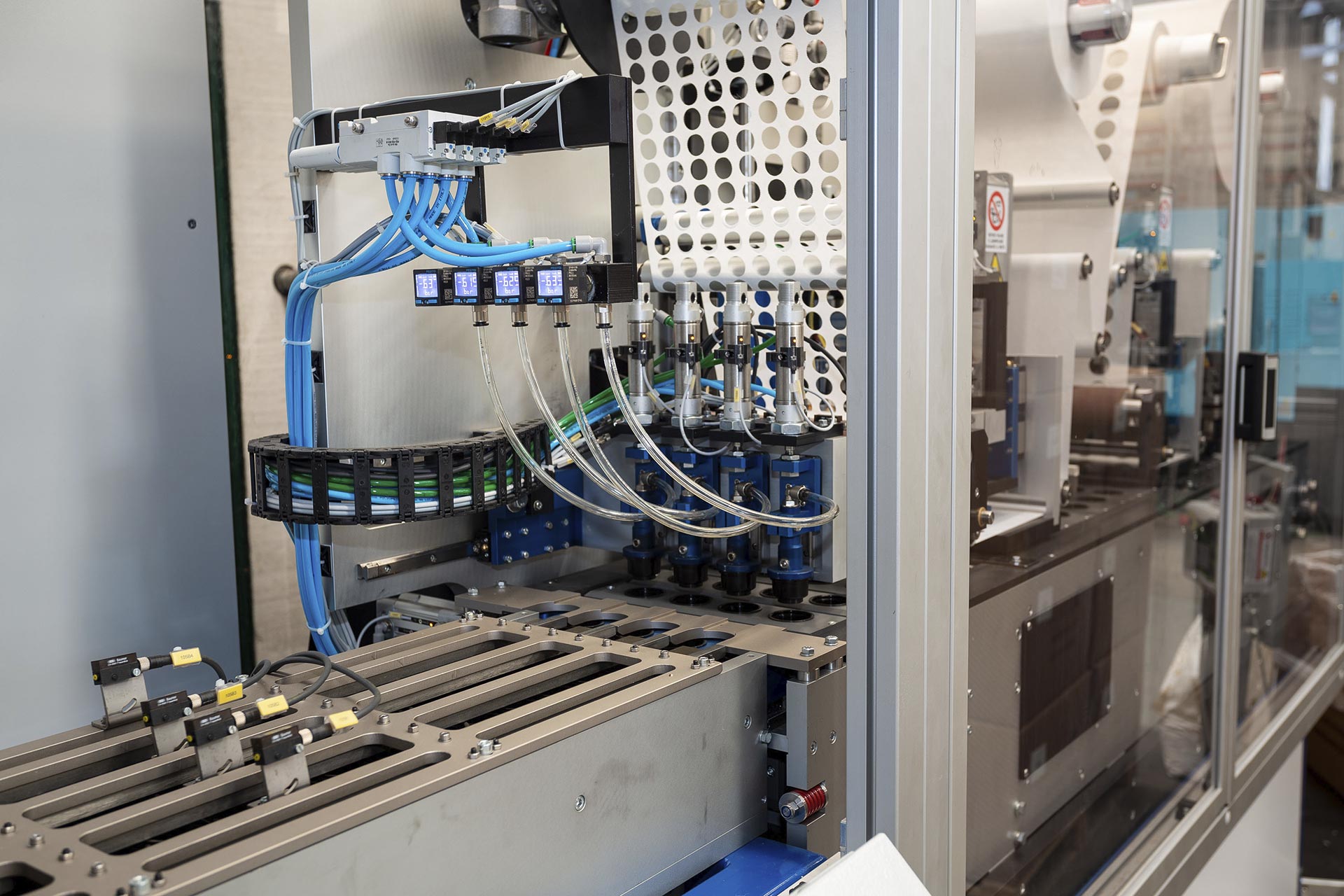

CUTTING-EDGE MACHINES FOR CONSISTENTLY RELIABLE RESULTS

Our machinery park includes electric injection moulding presses and equipment dedicated to the pre-packaging of capsules. We collaborate with industry leaders partners specialised in mould design for packaging, to achieve precise, high-quality results. All our products are made from certified raw materials and colorants, compliant with food contact regulations.

Thanks to a large finished goods warehouse, Diliplast can ensure immediate availability of standard items, guaranteeing fast and punctual shipping times.